BEF CNC FLANGE Drilling can process plates with thicknesses from 6 to 80 mm within the working area dimensions. The material to be processed is moved on the ball processing table by means of hydraulic clamping jaws. With CNC programming, the part positioned in the machining coordinates is fixed with hydraulic piston and hardened claw jaws and the drilling process is performed correctly. The BEF Flange Drilling Machine is capable of drilling, tapping, scraping, simple milling and hydraulic pressure reeling (ops).

Specifications

|

Control panel

|

Mitsubishi M70 V

|

Mitsubishi M70 V

|

|||||||

|

Drilling unit

|

|||||||||

|

Vertical

|

1 Unit

|

1 Unit

|

|||||||

|

Speed Range

|

10-3000 (RPM)

|

10-3000 (RPM)

|

|||||||

|

Tool Conical

|

BT 40

|

BT 40

|

|||||||

|

Moto Power

|

22 KB-T / kW / 140Nm

|

22 KB-T / kW / 140Nm

|

|||||||

|

Spindle Torque

|

280 Nm

|

280 Nm

|

|||||||

|

Working Capacity

|

|||||||||

|

Plate Dimensions Min. (mm)

|

100*100*6

|

200*200*6

|

|||||||

|

Plate Dimensions Max. (mms)

Dimensions are given according to maximum material weight that can be positioned.

|

1000*1500*64

1000*1190*80

795*1500*80

|

700*1250*40

|

|||||||

|

Plate Thickness minimax. (mm)

|

6/80

|

6/80

|

|||||||

|

Maximum material weight that can be positioned

|

750 kg.

|

500 kg

|

|||||||

|

Max.Drilling Capacity (mm)

|

40

|

40

|

|||||||

|

Tapping min./max

|

M10/M24

|

M10/M24

|

|||||||

|

Axis X Speed

|

20.000 mm/min

|

20.000 mm/min

|

|||||||

|

Axis Y Speed

|

20.000 mm/min

|

20.000 mm/min

|

|||||||

|

Axis Z Speed

|

15.000 mm/min

|

15.000 mm/min

|

|||||||

|

Other Features

|

|||||||||

|

Automatic Tool Changing (ATC)

|

16 / Units

|

16 / Units

|

|||||||

|

Machine Weight

|

~7250 Kr./~7250 kg .

|

~6500 Kr. /~ 6500 kg.

|

|||||||

|

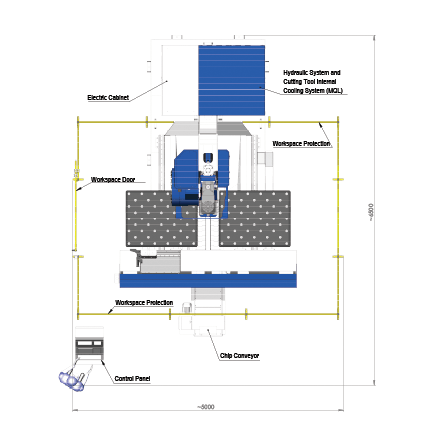

Area Covered by the Machine (mm)

|

-6500*5500*2550

|

15.000 mm/min

|

|||||||