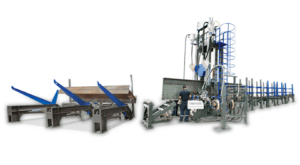

standard Features

- 359 ° Rotating column (manual)

- Mobile wired control

- V-type slide system designed for gap-free operation

- Adjustable linear boom speed

- Boom speed digital display

- Boom speed selection (fast / slow)

- Mechanical locking system against boom fall

- Boom counterweight system (Elevator)

- Limit switch in all movements

- Welding power unit stand (on column)

- Engines with brakes

- Cable trays on column-boom

- Ground fixing system

- Torch miter

- Manual controlled torch adjustment system (slide)

Optional Features

- Special wheel designs for high temperature areas

- Overhead Sleeper

- Common / Central Control Panel

- Automatic Rotating Column

- Operator Seat (with Ladder option)

- Camera Monitoring System

- Tandem Welding Equipment

- Lighting

- Stairs

- PLC Control with Inverters (synchronized operation system)

- Oscillator System (with MIG / MAG)

- Walkway (Rail system)

- SAW, MIG / MAG or TIG Welding Systems

- Welding Trace System – Laser

- Welding Trace System – Mechanical

- Powder Drying System (SAW only)

- Mobile Console

- Automation System

- Insulation According to Operating Conditions

- Double Head Welding System (SAW-Tandem)

- Twin Wire Welding System (SAW-Twin)

- Twin Wire Double Head Welding System (SAW-Twin Tandem)

- AC / DC Single Source Power Pack (SAW)

Specifications

|

S.No

|

Model

|

Max.Load Capacity[Kg.]

|

Min. Height Under boom [mm]

|

Max. Height Under boom [mm]

|

Overal Height[mm]

|

Boom Reach[mm]

|

Boom Reach[mm]

|

Rail Axis Range[mm]

|

Elevation Speed Up-Down[mm/min]

|

Boom Travers speed[mm/min]

|

Tracers speed Left/Right[mm/min]

|

Col Rotation angle

|

Elevator Motor Power[kW]

|

Boom or Travers motor Power[kW]

|

Weight[kg]

|

|

1

|

MCB-3*3

|

300

|

780

|

3080

|

4350

|

405

|

3000

|

1490

|

2000

|

200-2000

|

2000

|

360

|

0.55

|

0.37

|

3450

|

|

2

|

MCB-4*4

|

250

|

780

|

4080

|

5350

|

405

|

4000

|

1655

|

2000

|

200-2000

|

2000

|

360

|

0.55

|

0.37

|

3650

|

|

3

|

MCB-5*5

|

200

|

780

|

5080

|

6350

|

405

|

6000

|

1655

|

2000

|

200-2000

|

2000

|

360

|

0.55

|

0.37

|

3850

|

|

4

|

MCB-6*6

|

150

|

780

|

6080

|

7350

|

405

|

6000

|

1655

|

2000

|

200-2000

|

2000

|

360

|

0.55

|

0.37

|

4100

|

|

5

|

MCB-3*3

|

600

|

1000

|

30000

|

4080

|

830

|

3000

|

1490

|

2000

|

200-2000

|

2000

|

360

|

0.55

|

0.37

|

6400

|

|

6

|

MCB-4*4

|

500

|

1000

|

40000

|

5380

|

830

|

4000

|

1490

|

2000

|

200-2000

|

2000

|

360

|

0.55

|

0.37

|

6700

|

|

7

|

MCB-5*5

|

450

|

1000

|

5000

|

6380

|

830

|

5000

|

2420

|

2000

|

200-2000

|

2000

|

360

|

0.55

|

0.37

|

7000

|

|

8

|

MCB-6*6

|

300

|

1000

|

6000

|

7380

|

830

|

6000

|

2420

|

2000

|

200-2000

|

2000

|

360

|

0.55

|

0.37

|

7350

|

|

9

|

MCB-9*6

|

300

|

1100

|

9000

|

10500

|

850

|

6000

|

2420

|

2000

|

200-2000

|

2000

|

360

|

0.55

|

0.37

|

8650

|

|

10

|

MCB-9*9

|

200

|

1100

|

9000

|

10500

|

850

|

9000

|

2420

|

2000

|

200-2000

|

2000

|

360

|

0.55

|

0.37

|

9350

|