standard Features

- U PU ”castors to prevent impact and vibration

- Automatic diameter adjustments

- Adjustable rotation speed

- 5 meter wired remote control

- Digital speedometer for rotation tracking on the control panel

- Lining clutch system for high tonnage parts

- Engines with brakes

Optional Features

- Special wheel designs for high temperature areas

- Axial bearing

- Chassis – Brush Group

- On-Rail Motion System (Carrier System)

- Synchronous operation with column boom systems

- Rail

Specifications

|

S.No

|

Model

|

Load Capacity[tons]

|

Load Capacity per unit[tons]

|

Minimum Diameter[mm]

|

Maximum Diameter[mm]

|

Roller Diameter[mm]

|

Roller Width[mm]

|

Roller Material[mm]

|

Over all length ldler[mm]

|

Over all width ldler[mm]

|

Over all Length Drive[mm]

|

Over all Width Drive[mm]

|

Height over Roller[mm]

|

Motor Power[kW]

|

Weight[kG]

|

|

|

|

|

|

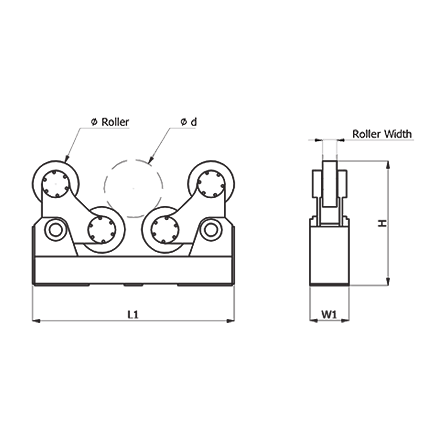

d

|

D2

|

0

|

|

L1

|

W1

|

L2

|

W2

|

H

|

|

|

|

|

1

|

SAR-3

|

3

|

1.5

|

235

|

2450

|

254

|

76

|

Polyurethane

|

1040

|

440

|

1340

|

570

|

515

|

1*0.37

|

350

|

|

2

|

SAR-5

|

5

|

2.5

|

400

|

3000

|

254

|

76

|

Polyurethane

|

1180

|

465

|

1480

|

530

|

515

|

1*0.37

|

400

|

|

3

|

SAR-10

|

10

|

5

|

450

|

4600

|

381

|

102

|

Polyurethane

|

2010

|

580

|

2500

|

730

|

930

|

2*0.25

|

1700

|

|

4

|

SAR-20

|

20

|

10

|

450

|

4600

|

381

|

127

|

Polyurethane

|

2020

|

660

|

2600

|

800

|

950

|

2*0.55

|

1900

|

|

5

|

SAR-30

|

30

|

15

|

450

|

5200

|

457

|

127

|

Polyurethane

|

2100

|

670

|

3100

|

900

|

1010

|

2*0.75

|

2700

|

|

6

|

SAR-40

|

40

|

20

|

450

|

5200

|

457

|

127

|

Polyurethane

|

2120

|

680

|

3200

|

900

|

1050

|

2*1.1

|

2900

|

|

7

|

SAR-50

|

50

|

25

|

450

|

5200

|

457

|

152

|

Polyurethane

|

2120

|

705

|

3200

|

925

|

1050

|

2*1.1

|

3200

|

|

8

|

SAR-60

|

60

|

30

|

500

|

5500

|

559

|

127

|

Polyurethane

|

2610

|

705

|

3750

|

1000

|

1310

|

2*1.1

|

4450

|

|

9

|

SAR-80

|

80

|

40

|

500

|

5500

|

559

|

178

|

Polyurethane

|

2610

|

850

|

3750

|

1200

|

1310

|

2*1.5

|

5000

|

|

10

|

SAR-100

|

100

|

50

|

600

|

6000

|

559

|

260

|

Polyurethane

|

2900

|

900

|

1400

|

1250

|

1320

|

2*2.2

|

6250

|

|

11

|

SAR-150

|

150

|

75

|

600

|

6000

|

559

|

310

|

Polyurethane

|

3020

|

1200

|

4500

|

1650

|

1385

|

1*5.5

|

7450

|

|

12

|

SAR-200

|

200

|

100

|

1000

|

7000

|

559

|

360

|

Polyurethane

|

3300

|

1250

|

4850

|

1700

|

1415

|

2*7.5

|

9100

|

|

13

|

SAR-300

|

300

|

150

|

1000

|

7000

|

559

|

203

|

Steel

|

3300

|

1050

|

4950

|

1550

|

1415

|

2*7.5

|

10000

|