Standard Features

- Control Panel: Mitsubishi

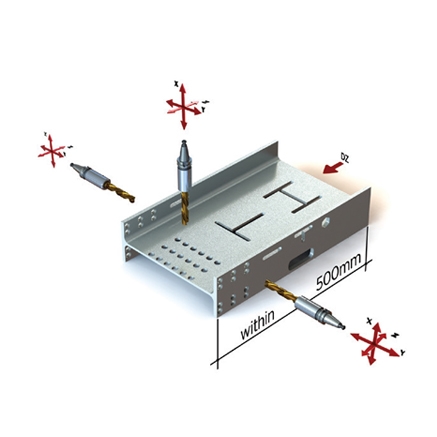

- Drilling Unit – Vertical: 1 pc Vertical

- Drilling Unit – Horizontal: 2 pieces Horizontal

- Drilling Diameter: 10-40 mm

- Spindle Speed: Infinitely variable 50-3000r / min.

- Spindle Motor Power: 22 kW / 140 Nm

- Spindle Torque: 280 Nm

- Motion Transmission System: Pre-tensioned screw shaft / nut system

- Automatic Tool Change Unit: 4 tool capacity per spindle

- Inlet Conveyor Length: 12m

- Output Conveyor Length: 12m

- Centralized Lubrication System: Standard

- Tool Cooling System: MQL

- Material Metretule Weight: 600 kg / m

- Threading tool for all three axes (optional): M10 – M24 (with special tool)

- Profile width max-min, with lower support unit: 1200/1500 / 1750-200

- Profile Height max-min: 500/600 / 600-80

- Drill Chuck Taper: BT 40 (with coolant passage)

- Workpiece movement: Planetary gear reducer

- Profile Length Reset: Standard

- Angle Band Saw Integration: Optional

- Weight: 13000 kg

- Dimensions of the machine: 2400 x 7000 x 3200 mm

- Hydraulic Marking: Optional

- Scratch marking tool: on all three surfaces

- Chip Conveyor: Standard

Specifications

| TECHNICAL INFORMATIONS | B3DL 1200 | B2DL 1200 |

| Control Panel | Mitsubishi / Siemens | Mitsubishi |

| Drilling Unit- Vertical | 1 Vertica | 1 Vertical |

| Drilling Unit- Horizontal | 2 Horizontal | 2 Horizontal |

| Drilling diameter | 10-40 mm | 10-40 mm |

| Spindle Speed-Infinitely | Infinitivel10-3000 d/min. | Infinitivel10-3000 d/min. |

| Drive Power Per Axis | 22 kW / 140 Nm | 22 kW / 140 Nm |

| Spindle torque | 280 Nm | 280 Nm |

| Movement Transmission System | Preloaded ball screws / nut system | Preloaded ball screws / nut system |

| Automatic Tool Changing Unit | For each spindle one ATC with 4 tool | For each spindle one ATC with 4 tool |

| Infeed Table with CNC Carriage | 12m | Strandard 12m Material |

| Exit Table with Motorized | 12m | Strandard 12m Material |

| Central Lubrication for Linear Guides | Standard | Standard |

| Tool Cooling System | MQL | |

| Weight of Linear Meter | 600 kg/m | 600 kg/m |

| Tapping Tool for all three execs (Optional) | M10 – M24 (with special set) | M10 – M24 (with special set) ` |

| Beam Width max-min with support from down | 1200 / 1500 / 1750-200 | |

| Beam Height max-min | 500 / 600 / 600-80 | 500/80 mm |

| Spindle Head Tool Shaftshole | BT 40 With cooling liguid long hole) | BT 40 With cooling liguid long hole) |

| Workpiece movement | Servomotor + planetery gear box | Servomotor + planetery gear box |

| Automatic Cross-Section Measuring | Standard | Standard |

| Miter Band Saw Machine Integration | Optional | Optional |

| Weight | 13000 kgl | 11000 kg |

| Dimensions of the Machine | 2400 * 7000 * 3200 mm | 2300 * 5400 * 3050 mm |

| D.O.T. Marking | Optional | Optional |

| Scribing Tool | On one side | On one side |

| Chip Conveyor | Standard | Standard |

Note:- Standard and optional accessories shown and mentioned are indicative. An offer will contain all aspects of supply. The above is only for an Idea.