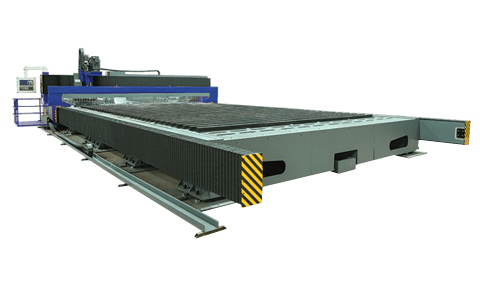

Standard Features

- 3 Axes CNC

- High machining efficiency

- High positioning accuracy of spindle

- Manual part fixing

- Drilling, threading and surface scanning (simple milling) operations with a spindle

- Chuck for manual quick tool change

- Marking on the plate with special milling cutter

- Powerful drill cooling circuit with liquid and air mixture

- Max. workpiece (mm): 2000 × 3000 (may vary by request)

- Max. Drilling diameter (mm): Ø75

Specifications

|

Control panel

|

SIEMENS

|

||||

|

Drilling unit

|

1 vertical

|

||||

|

Drilling diameter 0

|

/10 -50 mm (tool with replaceable carbide head / 50-75 mm with U-tool)

|

||||

|

Spindlerevolution

|

10 – 3750 o6/man (d/dak).

|

||||

|

Spindleengine power

|

Ha / 1500 06/am – 06/mai-i/ 30 idlr / 191

|

||||

|

Spindle Torque

|

Nm / 382 Nm / 750 o6/awn (rpm)

|

||||

|

Max. travelling speed under no-load condition(forard-backward)

|

lOrn / min.

|

||||

|

Movement Transmission system

|

Preloaded ball screws.

|

||||

|

Automatic tool changing unit (ATC)

|

BT40-1 PIECE – 8 TOOLS

|

||||

|

Central lubrication system)

|

Standard

|

||||

|

Cooling system

|

Internal tool cooling (for carbide drills) BT40 mandrel with hydraulic tool clamping new with BT40)

|

||||

|

Screw tapping

|

M12 – M30

|

||||

|

Material width

|

10-100 am / 10 to 100mm

|

||||

|

Rich Chuck Cone / Spindle Head Tool Shaftshole

|

BT40.(suitable for ATC system)

|

||||

|

Work piece

|

Fixed

|

||||

|

Work piece weight (max)

|

5000kg

|

||||

|

Chip Conveyor

|

Standard

|

||||

|

Machine dimensions

|

7500*4900*2950

|

||||

|

Weight

|

21500 kg

|

||||